Tip 1

Pay attention to the viscosity of the oil. The result of the search for images for the query "oil viscosity"

One of the main criteria for a quality oil is its viscosity.

In fake oils, much less special additives and thickeners, so non-original composition may be unacceptably liquid.

Unfortunately, this does not always come out right away. If quality fake, then at normal temperature, the oil will have a normal thickness.

Cheating is already in the process of exploiting when checking the level of oil on a well-heated engine.

Tip 2

Take a look at the label.

This way of detecting a marriage is very simple, but effective at the same time. Pay particular attention to what kind of label is marked on the date of manufacture.

The digits should indicate the date of production, the time, the batch number. In this case, the information on the label should be exactly the same as the one on the canister.

In case you find a mismatch or do not have manufacturing on the label at all, then in your hands with a 99% probability fake.

Tip 3

Evaluate the oily properties of the product.

After the purchase, do not hurry to use the oil immediately after use - check it.

First, roll a little lubricant on your finger and appreciate its structure, oiliness.

Second,

take a prepared transparent container, pour a little oil in it and put

it in a dark place for at least 5-10 minutes. After that, carefully

inspect the product. The oil should not have signs of flaking, its consistency should be

homogeneous, no trace of siege, and dark particles should not be.

Tip 4

Pay attention to the color. Distinguish quality butter from forgery, Top 6 tips from an expert

Before pouring oil, evaluate not only the viscosity, but also the color.

Ideally, it should have an amber hue. If the color of the product is too dark, this may indicate a poor quality of the product.

Tip 5

We check the oil on the quality of additives.

For this experiment, we will need a pre-prepared sheet of paper (preferably A4). Take a little bit of motor oil to it. Keep the paper slightly under the slope so that the oil drips and

managed to absorb a little into the fibrous structure. We distinguish

high quality butter from forgery, Top 6 tips from an expert

If, after passing the lubricant on the white paper, there are dark

spots, then you can be sure of the presence of poor-quality additives.

Tip 6

Pay attention to the place of sale of the product and its price.

If you are "lucky" to buy oil from a famous brand at a very low price - do not hurry to rejoice.

In most cases it is a fake. Try to buy oil exclusively in branded stores, the cost of which may be

slightly more expensive, but you will be assured of quality and save on

repairs.

Let's summarize

So, let's summarize the difference between fake motor oil from the original product:

first, there are too few additives in the forging, or they are absent altogether;

and secondly, the non-original product has a less viscous texture;

Thirdly, the dark orange color is an obvious evidence of a fake;

Fourth, the original does not freeze in its proper temperature regime, the fake can crystallize at a small minus temperature;

fifthly, counterfeit oil has a lower price than the original.

What can be concluded? Do not save on your car.

Choose Orlen Oil high-quality oils and your car will always work!

Last news

Show by period:

- All news

- Last month

- Last 3 months

- Last 6 months

- Last year

December 25, January 1 and January 8, LOKO will not work.

Congratulations on coming holidays!

Every

car owner knows well that car should be looked after, otherwise it will

not be comfortable to ride on it, and soon it will be impossible. In order for the car to please the owner, he needs care, especially in the winter.

Very often and not pleasant for car owners the phenomenon of snowfall. Depending

on the frequency of snowfall, but at least once a week, you should

check the windscreen tank to ensure that it does not end in at the most

appropriate moment. The sink is definitely important, but if you do not have a wipers,

then the effect will be zero. Check the work of the wipers before each

departure, but do not just check whether they are moving or not, and

check how they remove wind turbine from the windshield.

Also,

one of the problems in zimki is the smelting of glass, since a rinse

gets some amount of snow that will melt, and as a result, glass can

sweat. To prevent this, it is necessary to wash and dry the mats from time to time.

Winter tires wear out much faster because of the soft tread, so at least once a month check the balancing of the wheels. It should not be forgotten about the timely pumping of tires,

because because of temperature fluctuations pressure in tires can

change, which does not very well affect the coupling properties.

Water freezes at zero degrees, and in car washes the machine washed with water. It

follows that the water is freezing there, where it has fallen, and

since it will get into all openings on the sink, then after washing it

is necessary to wipe the outer parts of the locks thoroughly and it will

not be unnecessary to blow them with a jet of air, so that they do not

freeze. Well, if you treat them special liquid, it will be even better.

If

you often have to make not large trips, it is likely that soon on the

candles will form a scum, which worsens the engine start. There are two ways to get rid of the scum: with the twist of candles and without the dismantling of candles. As it is clear, it is clear when cleaning candles with disassembly candles are twisted and cleaned of scum. To

get rid of the scum without dismantling the candles, you need to find

the opportunity to ride in a straight line at high revs, then the fire

burns. The best way for this method is to travel around the city.

The battery needs to be recharged once and a half months, so that one

morning it will not let you down, as the load on it increases in winter.

It

is necessary to include the conditioner in the winter, because if the

air conditioner is not included, the rubber seals may lose tightness. To prevent this, turn on the air conditioner several times a month for 10 to 15 minutes at the operating furnace.

Any

driver does not like the slippery road, but much more does not like the

salt that the dirt is poured into, so that it does not turn into a

skating rink. It's hard to say that it is not useful, and if the car is

not washed, then the salt will start to roar. 'Carry parts and cause corrosion. When washing, do not forget about the bottom and wheel arches, which are most affected by salt. If possible, cover the machine with a layer of wax, it will not allow

the salt to come into contact with the body of the vehicle.

Love your car!

Today, we offer to talk about the actual, namely, the winter washbasin glass. It would seem that there is nothing simpler, but not all is so simple.

Let's try to figure out how to choose a winter washbasin glass and what should pay attention to first:

Look at the warehouse

The main ingredients used in the preparation of the washer are alcohol and water. When choosing a winter washbasin, you first need to look at the

quality and type of alcohol used by the manufacturer, because it is the

main ingredient.

Methanol

The liquid containing methanol is considered to be the most affordable. This

alcohol has an affordable price, but there is one "but", methanol

refers to strong poisons that affect the nervous, as well as the

vascular system. Think about your safety and always read the composition before you make a purchase. If the winter washbasin is odorless, then you should be careful, because the methyl alcohol is exactly the same.

Ethanol

Such alcohol is the most safe and relevant to date. The only minus is a high price, so the demand for such an option if it is, then it is extremely rare. In essence, it is familiar to all vodka, only odorless and mixed with water.

Couples flying in air when using a washer on ethanol will not affect the state of health of the driver and his crew. As with methanol, pure ethyl is practically odorless. Its use does not cause any discomfort.

Isopropyl

Winter washer washer based on isopropyl alcohol - one of the most advanced. Concentration of vapors is not able to harm the driver and his passengers.

The only disadvantage of the washer based on this alcohol is a

specific odor that resembles acetone, so in expensive and high-quality

fluids, special "mufflers" are used to get rid of it.

Bioethanol. This

kind of liquid for a tank of a washer is the most expensive. This

liquid contains bioethanol, roughly speaking it is the same food alcohol

that is mixed with surfactants. There is no danger to this glass washer, but you will agree that it is

easier to buy vodka for such money and to pour it into the windscreen

tank, diluting lightly with a gel for washing the dishes, will be no

worse, at least to -30 ° is not exactly freezing.

How not to buy a fake!

Good advice:

1. Do not run on the low cost of the washer.

2. Watch not only for what you buy, but also for where you buy. In a serious automobile shop with all certificates and licenses, you are unlikely to slip a fake.

3. When choosing a window wiper, pay attention to the label, it should be informative. The bottle should contain information about the manufacturer, the composition, and barcode. All inscriptions and markings must be clear.We hope this information will help you to choose a quality washer!

Take care of yourself and your car!

Many drivers, unfortunately, do not understand the peculiarities of driving under such weather conditions. When the tires fall on ice, their grip on the road immediately drops 4-5 times, which in turn increases the braking distance of vehicles several times. And this means that a quick stop of a car is simply impossible. Such road conditions require drivers and pedestrians to pay more attention to their own safety measures and perfect compliance with the Road Traffic Rules.

In this regard, we want to give some recommendations on driving under ice conditions and snow rolled up:

On a slippery road, do not slow down dramatically, it's not only useless, but dangerous. Sharp braking leads to locking the wheels and increasing the braking distance, and more often than not, to the loss of controllability. When passing a dangerous area, try to keep the speed constant, use the accelerator pedal very carefully, smoothly and gently. Do not make sharp movements with a wheel.

When driving on bridges and overpasses, be especially careful. The ice layer on these areas of the road appears earlier than everywhere, and disappears later. In these areas, avoid sharp movements with a steering wheel, gas, and brakes.

On a slippery road it is better to avoid sharp maneuvers and overtaking. When driving on a climb, choose such a transmission so that you do not have to switch until the complete lifting is complete. During descent, do not press the clutch pedal, slowly brak when driving the car.

Do not forget about pedestrians. People crossing the road can slip and fall. So try not to scare the pedestrian with sharp audible and light signals. Get closer to pedestrian crossings and locations for children's facilities to minimize their speed.

Under snow conditions, it is necessary to move with the included dipped beam headlamps (or fog lamps), to adhere to high-speed mode, parking rules (in order not to interfere with the work of snow-removal equipment), with special care to move on bridges and overpasses, to refuse from risky maneuvers, which in unfavorable weather conditions can lead to emergency situations. If you need to stop, slow down the speed. And when stopping, turn on emergency light signaling.

In case of important and urgent needs driving you on the road, follow all the requirements of the rules of the road, be careful and careful, especially during the dark.

At the same time, the danger of oil overflow in the engine in the driving schools is rarely spoken, and outside of such information rarely comes to our ears, so the "people" has developed a stereotype that ignoring the mark "MAX" does not threaten any serious car. But is it really? Let's understand.

So what will happen if you pour oil in the engine?

In fact, the excessive presence of oil in the lubricating engine system is as harmful as insufficiency, as it can provoke the following problems.

Increased fuel consumption

The increased wear of the motor is due to the fact that the excess fluid in the engine adds the level of resistance of the piston stroke in the engine cylinders. Consequently, the movement of the kneeling becomes complicated, and the torque from it passes to the leading axis of the car. As a result, the processing and additional wear of the motor through overcoming the artificially created resistance in addition to the greater pressure of the driver on the gas pedal.

Increased amount of carbon in a car engine.

This is both an engine failure and internal components of the combustion chamber.

Rapid pollution of the muffler.

It reduces the possible period of its operation. Rapid and sharp increase in emissions into the environment of exhaust gases, deterioration of their quality (increased toxicity and poisoning). Hence the advice: if there is a need to warm a car with a deliberately high level of engine oil in the engine in a closed room (garage), you must try to provide yourself and your relatives with maximum safety, by preventing their long stay in one room with a warming vehicle.

Increased fluid flow

Always leads to additional costs.

Failure of eyelets.

They can be simply extruded under the pressure of too much engine oil pressure.

Oiling spark plugs and their premature wear.

The overflow of oils in the engine almost always leads to the masking of spark plugs because of their constant presence in the liquid.

The most dangerous for cars is the frozen and viscous fluid in hydraulic systems. If water in ice is converted into ice, then even frost-resistant solutions become viscous, losing their basic properties and thereby causing irreparable harm to the most important mechanisms. This applies to the oil in the engine and transmission box, brake and coolant in the corresponding systems, the lubrication of suspension hinges, the contents of the shock absorbers and the hydraulic booster, the electrolyte in the battery.

In order not to expose a car to a serious test it is better to adhere to several rules. Even if the engine at idle turns into the working temperature in a high frost, this does not mean that all other hydraulic systems have been throttled to the end. Therefore, moving from place to place and breaking the first kilometers of the way into the cold crash, move slowly, no more than 40 km per hour, avoid uneven road cover, possibly minimizing the load on the suspension as much as possible. Be prepared for the inadequate operation of the braking system due to the possible icing of the brake discs and pads. Treat the pedals gently and tenderly.

As practice shows, usually all systems start to work in the usual mode after 4-5 kilometers of the way. In addition, be prepared to suddenly show the vibrations on the steering wheel due to ice and snow on the wheels at a speed of 60 km / h. In this case, you have to drive to the sink and wash the wheels with a jet of water under the temple.

By

pouring or changing the coolant in the car, what is the difference

between the red, green and blue antifreeze, are at least hostile by all

newcomers-car owners. And

sometimes such questions are taken up by experienced drivers: yet the

science of production is not in place, every day put on the shelves of

stores something new. So the information checked over the years may well be outdated.

Experimenting with their car is not enough - such experiments are often threatened by rapid, inexpensive and long-term repairs. Therefore, people start to read carefully in small letters on

banks, carefully compare everything that manufacturers have managed to

write on them - and they are often surprised, not knowing how much one

liquid differs from the other.

What is the difference between red, green and blue antifreeze, meanwhile, to understand quite easily. And this knowledge in the future will help to determine what exactly to pour into your car. Why do I need a color?

First, any coolant is colorless. It receives its color from dyes added at the final stages of production. And the bright color has 2 goals:

• warns that in the container - chemistry, not ordinary water;

• serves to make it easier to determine where the fluid flows from, if the cooling system has run out.

The cooling effect does not affect the color of the antifreeze, they remain the ones that are planned at the factory. However, in recent times, color is still tied to certain parameters.

What is important to pay attention to?

The

composition of all these liquids is approximately the same, they differ

only in proportions and additives, individual in each manufacturer. But it should be remembered that the basis of antifreeze can be two types:

• silicate. Antifreeze, having it in composition, envelops the whole system, forming a thin film. Due to it, the circulation of heat decreases slightly, therefore, the efficiency of the cooling system decreases somewhat. Antifreezing silicates often have a blue or green color.

• carboxylate. Due to a radically different chemical origin, such a cooling fluid covers only places that are particularly prone to corrosion. Carboxylate serves longer, costs more and is usually painted in red.

However, the color separation is not obligatory: the silicate may be red, carboxylate is blue. The only thing that is very important to watch is the chemical composition of the antifreeze. Mixing coolant of different origin is not possible.

Not every owner of such technology knows exactly how to check the level of oil in automatic transmission. In cars with automatic gearbox it is very important to control the level of the transmission fluid. The main rules of how to check the oil in a box of this type

include the heated engine, as well as the position of the lever of the

choice of range in the position "R" - "Parking".

RVD in an automatic box is introduced in this position with long parking: it is then the movement of the car is blocked.

Necessary steps to check

In order to correctly check the level of oil, you must perform a number of actions:

1. Start the car and drive it at least 15 km in order to allow the oil to warm up to the working temperature - 66-93⁰С.

2. Having checked that the transmission fluid is sufficiently warmed

up, it is necessary to stop the car, but it is not necessary to muffle

the engine.

3. It is very important to place a car on an equal and horizontal

surface, it is with this condition that the correct check will be

obtained.

4. When the wheel is locked, the driver must consistently move and hold the gear selector in all positions for about 5 seconds. This is done so that the oil is evenly distributed over the hydraulic system.

5. Then the lever is finally moved to the "R" mode. In order to check the level of oil in the box, in some models the selector should be left in the "N" - "Neutral" position.

6. After that, the brake pedal must be released.

7. Under the hood is necessary to find a probe - a metal rod for measuring the level of oil in automatic transmission.

8. This metal rod should be gently wiped with dry matter and rotated to the point until it stops. After that you need to pull it out again.

9. On the probe there are usually a few inscriptions or inscriptions. It

is possible that the labels will be in the form of "Full" and "Insert",

then the acceptable level of oil in the automatic transmission should

correspond to the drop of oil between the two symbols. If these labels are four, most likely, the upper two will be labeled "Hot", and the bottom two will be "Cold". The first ones are needed for checking in a hot box, and the second one is for cold. It

is important to understand that it is not possible to make measurements

correctly at a cold engine, and there will be no exact indications. To get the right result, you need to clearly understand how to check

the oil level correctly, and for this purpose it is necessary to warm up

the car and use the "Hot" mark on the measuring probe.

10. If it is necessary, it is not necessary to add more than 0.5 liters. Here's another question: how to check the level of oil after it is flooded? To do this, do not immediately measure the level, but you must wait at

least 10 minutes before checking the oil in the ACPP again.

11.

After making sure that the oil level indicator in the box is optimal,

you should insert the probe into place so that its top part adheres

tightly to the neck. This will save the AKPP from falling into it such foreign particles as dirt or water.

Timely oil change in the engine of an excavator or other special equipment is an important factor in maintaining the performance of the power plant of the machine. Many operators of special equipment are rather negligent to replace the engine oil - forget the timing of its change or deliberately stretch the oil exploitation period, hoping for savings. Orlen Oil specialists are urging owners of special equipment to strictly monitor the periodicity of the replacement of motor oils, since this procedure substantially minimizes the risk of engine breakdown and ensures its efficient operation.

In the replacement of engine oil two rules should be guided:

• Replacing the oil in the engine after working out 250 mph / h;

• Replacing engine oil after 35 hours of work changes.

It should be noted that in conjunction with the change of oil should be changed and oil filter, because the oil and filter, which worked the above term significantly lose their performance and do not provide protection of the engine.

Among most popular олив in our assortment can offer: Hydrol L - HV 46, AGRO STOU 10w-30, AGRO UTTO 10w-30, Platinum Multi PTF 10w, Platinum Multi UTTO 10w-30 et al.

In an order to get consultation on a selection and also for the order of олив call to our skilled specialists.

As

there is a severe competition in the field of road freight transport,

truck owners demand the highest performance from their vehicles. Buying

motor oils for trucks is a very important step, because this vehicle

has to carry out tasks for long-distance cargo delivery. Therefore, we recommend not to save, but to buy only the best oils

that fully meet all your requirements, as well as protect the engine

from possible breakdowns and rapid wear.

It is among the wide assortment of LOCO oil that you will always find from the one that suits your car.

Platinum Ultor Extreme 10W-40

The

latest generation of semi-synthetic motor oil, specially developed for

new diesel engines, which operate in conditions of increased complexity

with a maximum interval between replacements, simultaneously fulfills

the basic standards of Euro V. The unique composition of synthetic and

mineral bases for any conditions is supplemented with a set of

high-quality additives of the new generation, which ensures that the highest European requirements of

the ACEA, API and car manufacturers, as well as environmental protection

requirements are met.

Platinum Ultor Extreme provides:

• Large intervals between substitutions,

• Clean the engine due to the soot holding in the suspension,

• Maximum engine power

• Compliance with emission standards Euro V, IV, III, II, I

• Significant reduction of costs associated with the operation of the car park,

• Compliance with the main requirements of car manufacturers.

Application

The Platinum Ultor Extreme oil is intended for all new Euro V diesel engines equipped with SCR catalysts. This oil can be successfully used in cars of early designs complying

with the requirements of Euro IV, III, II, I. Also recommended for

heavy-duty gasoline engines.

Standards, Harmonization, Specifications:

MAN 3277

MB-APPROVAL 228.5

VOLVO VDS-3

RENAULT VI RLD-2

MACK EO-N

TATRA TDS 30/12

Meets the requirements:

MERCEDES-BENZ 228.3

MTU OIL TYPE 2

MAN 3275

VOLVO VDS-2

DAF

In

order to get advice on the selection and also order motor oils, you

only need to call us and discuss all the options for ordering and

delivery of selected materials.

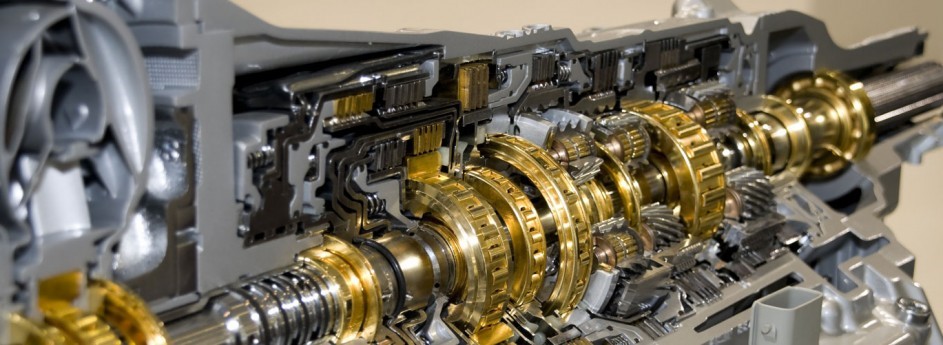

Transmyssyonnoe oil - is Special type of oil kotoroe Created for use in hydrousylytelyah rulevoho management, razdatochnыh boxes, gears, axles, mechanical and of automatic transmissions. The main thing Requirements for transmyssyonnomu oil zakljuchaetsja in abilities and made the uderzhyvat on the surface of parts transmyssyy maslyanuyu plёnku, kotoraja will be vыderzhyvat High load, sozdavaemыe in the process of work equipment.

Transmission oil marking

By marking the transmission oil it is possible to outrun mineral oil or synthetic, the correspondence of this oil with the quality standards, its SAE viscosity and many other characteristics. For example: ATF, Dextron and Dexron inform that this gear oil is intended for automatic gearboxes. This is due to the fact that neither automatic transmissions nor motor oil can be used for ACP. The oil marked ATF, which is decoded as Automatic Transmission Fluid, has a low viscosity and is applied exclusively in automatic gearboxes.

Below, in the article, we will consider the main indicators presented on the labels and accompanying documents when describing the properties of transmission oils.

Transmission oil API characteristics

The API parameter characterizes the performance characteristics of the transmission oil, such as the type of oil and its scope, is indicated by the letters "GL" with a number from one to five:

• GL-1 - mineral oil without any additives affecting its properties;

• GL-2 - oil in the composition of which there are fat components, such oil is used in industrial equipment and worm gear types;

• GL-3 - oil has anti-drain additives, used in rear axles, mechanical and helical-conical gearboxes;

• GL-4 - in addition to anti-closure, it also contains anti-wear and a number of other additives, used in spiral-conical and manual transmissions;

• GL-5 - has a large set of additives among which are prototype and anti-perceptual, used in hypoid and a number of other transmissions.

Applicability of transmission oil

The use of this or that type of oil directly depends on the requirements of the manufacturer of special equipment. Therefore, we encourage you to adhere to the requirements specified in the instructions for use and not to use oil with a lower API level. Let's consider the general principles of application of gear oil depending on the indicator "GL".

In most cases, GL 3 oil is required for the transmission of trucks (without hypoid gears), but in some cases GL 5 oil is used for check points and bridges of some machines.

In passenger cars and hruzovыh ymeyuschyh reduction gears with hypoydnыm way stseplenyya shesterёnok prymenyayut oil GL 5.

This with topics such oil something pomozhet avoided zadirov appearance on zubyah gears.

In the transmission of passenger cars it is customary to use GL 4 oil for mechanical gearboxes and GL 5 oil for lubrication of driving bridges

SAE Transmission Oil Performance

The parameter SAE (viscosity class) characterizes changes in the viscosity of the oil at different temperatures and allows you to split the gear oils into three categories:

• Winter oil - SAE 75W-90 works great in the cold season (with the letter W in the marking);

• summer oil - SAE 140 and 250, used in warmer seasons or in countries with hot climates; in temperate climates, it is desirable to use oil of class 90 (W in the absence of marking);

• vsesezonnoe Oil - SAE 75W-90, 80W-90 and 85W-90 and acknowledged unyversalnыm Using podhodyt for year-round (and letnyaya zymnyaya labeling pyshetsya through defys).

Orlen Oil offers high-quality Transmission oils TRANSOL, TRANSOL SP, TRANSOL CLP, TRANSGEAR PAG, TRANSGEAR PE. Of industrial gear oils for TRANSOL poluchayut IZ ochyschennыh myneralnыh oils with additives îíè soderzhat antykorrozyynoy, antyokyslytelnыm, protyvopennыm and deэmulhyruyuschym action. THEY zaschyschayut Separate elements of transmission (gears, bearings rolling and skolzhenyya) from chrezmernoho mechanical yznosa in the process of operation, zaschyschayut konstruktsyonnыe elements transfer from corrosion Due the chemical Impact aktyvnыh components of oil and of products ee oxidation, Thanks to Peak termookyslytelnoy stabylnosty obespechyvayut dlytelnuyu works at High temperatures without loss of Their properties.

1. If the oil is dark, then it is necessary to change it, regardless of the mileage of the car. In fact, cleansing additives dissolve incomplete fuel combustion products, keeping the engine clean and protecting against contamination, so oil and darkens.

2. It is possible to "on the eye" determine the period necessary for oil change. You should adhere to the periods recommended by the manufacturer of your car.

3. It is necessary to adhere to one interval of replacement of motor oil for all types of transport. If, for cars of different brands, the dates of oil change can be approximately the same, then for commercial vehicles it is necessary to calculate periodicity taking into account the operating mode.

4. It is not necessary to change the oil regularly. In fact, if you skip only one oil change, the deposition in the engine will be much more intense, which will result in deterioration of the lubricating motor and slow down the oil circulation, which can cause an increase in engine wear, as well as its possible breakage.

5. The oil is more expensive, the better it is. Even the most expensive oil can be harmful if it does not meet the requirements of the manufacturer of the car, so the main criterion when selecting a motor oil should be not the price, but the instructions in the operating instructions.

6. Synthetic and mineral oils have no significant differences. Mineral oils are rapidly oxidized and lose the main characteristics of operation. Synthetic oils are much more resistant to temperature conditions and maintain their operational properties for a much longer period, which is the main reason for their use in cars with increased interservice intervals.

7. For cars of the early year of release only mineral oils are suitable. This mistake is associated with the fact that when synthetic oils only appeared on the market, when they were poured into a car, drivers spotted the oil under the car. The explanations of such cases are very simple: the oil, getting into the engine, begins to actively interact with it, effectively washing the contaminants accumulated everywhere, including the location between the shaft and the gland. As a result of deep cleansing, the gap between them increased, and the engine oil began to flow out.

8. All season oil is worse than seasonal. There are no differences, especially since the largest manufacturers begin to offer on the market only all-season oils.

9. It is impossible to test the quality of motor oil at home. There is a method that determines the suitability of the oil. Put a drop of oil on a newsprint, and it will blur, leaving the concentrated circles. If the drop steadily keeps its shape - then the oil is time to change.

10. Diesel engines require more frequent oil change. The decisive factor is the quality of fuel for a diesel engine. If it complies with European standards, it will often not be necessary to replace oil.

Today we are opening an authorized Platinum service in Uzhgorod.

We are ready to welcome guests and present the PLATINUM oils!

Good morning, friends!

We want to share with you several photos from the largest agro-industrial exhibition "Agroexpo" in 2017.

Morning coffee and award "25 years of LLC" Loko ". Together we accelerate the future of Loko and Orlen Oil "from our Polish partners to make our morning special.

So we are 25 and we are proud of that! We sincerely thank our clients and partners, because without you we would not become the ones we are now.

Good morning, friends!

The largest international agro-industrial exhibition "Agroexpo" has begun!

We are waiting for everyone who wants to visit our booth and learn a lot about our oils!

Date: September 20-23, 2017

Place: Kropivnitsky, st. Murmansk, 8.

The International Agro-Industrial Exhibition "AGROEXPO" is the largest Ukrainian agro-industrial exhibition and is located in one of its most important agrarian regions.

The total area of "AGROEXPO" is 100 000 m2 and includes both open and closed exhibition areas.

A unique feature of AGROEXPO is the opportunity to see in operation all types of agricultural equipment at a demonstration site for field testing with an area of 60,000 m2 in close proximity to exhibitors' exhibits.

The company "LOCO" invites everyone to visit the Agroindustrial Exhibition, to wait for you:

1. A large number of thematic exhibition exhibitions, in particular: crop production, livestock, transportation and special equipment, processing and logistics of products, alternative energy in the agro-industrial complex, etc.

2. Specialized exhibitions, in particular: "BUDEXPO", "AUTOLAND".

3. Field displays and tests of specialized equipment.

4. The Intercession Fair.

5. Competitions and entertainment.

We will be waiting for you at the exhibition of LOKO LLC, where you can get acquainted with the products of Orlen Oil, in particular with a line of oils for agricultural machinery Platinum Agro.

Today, agriculture is an emerging industry. In order to achieve high yields and to cultivate large areas, it is necessary to use modern technology. In this regard, there is a gradual replacement of machines with modern and efficient equipment. Accordingly, for the efficient operation of the equipment, it is necessary to observe the rules of its service, in particular, it is necessary to adhere to the rules of replacement of oil in agricultural machinery engines.

Every owner of agrarian machinery faced with such a question as to choose the right oil for agricultural machinery.

The main negative factor influencing the systems and mechanisms of agricultural machines is the high temperature. This is due to the fact that agrotechnique works predominantly during the warm period of the year. Therefore, it is important to add special additives, due to which the oil does not boil at high temperatures.

Selection of oil for agricultural machinery

First of all, we recommend that you choose oil for agricultural machinery in accordance with the requirements of manufacturers of this technology and use oil that meets the requirements and characteristics of the machine. The use of lubricants recommended by the manufacturer allows you to keep the equipment from premature wear and protect it from sudden breakdowns. In the event that the owner of the machinery is not able or willing to use the brand that is recommended by the manufacturer of cars, a new type of oil should be selected taking into account three main characteristics:

• oil viscosity - SAE,

• standard - ACEA, API;

• compliance with the requirements of a particular manufacturer of the machine.

Requirements for the characteristics of the oil for agrotechnics.

The main requirement for oils for agricultural machinery is to maintain the working capacity of the units and aggregates of these machines. However, for each type of oil there are its peculiarities which should be taken into account by consumers of lubricants.

The oil used in agricultural machinery engines should:

• reliably hold oil film on the surface of the ICE;

• to prevent the formation of foreign deposits with the use of high-sulfur fuel;

• prevent the formation of rust;

• reduce the toxicity level of combustion products;

• clean the engine from contamination;

• Protect engine parts from wear during cold start.

The oil used in the transmission and hydraulics of agricultural machinery should:

• protect parts and mechanisms from wear;

• provide reliable operation of brakes and other parts of transmission and hydraulics;

• be resistant to foam formation;

• promote smooth and even movement of all elements of the above systems;

• Do not destroy the seals and seals of rubber, polymers and other materials;

So, from the choice of oil to a large extent the lifetime of the agricultural equipment depends, we recommend that you pay attention to the line of Platinum Agro Oils, which is specially developed for modern agricultural machines, the Polish manufacturer Orlen Oil.

The latest technology used in Platinum Agro Oils provides a guarantee of the safety of machines and equipment that works in agriculture.

Platinum Agro Oils form a solid, oily film in full use, and effectively neutralize combustion products. Increase protection against corrosion, thereby increasing the accident-free life of the machines.

Excellent lubricating properties contribute to the savings associated with an increase in the period between oil replacements and reduced fuel consumption.

High quality motors, transmissions, hydraulic and multifunctional Platinum Agro oils meet the requirements of leading manufacturers of agricultural machinery, including John Deere, Massey Ferguson, Case, New Holland, Same, Deutz-Fahr, Claas, Fendt, Zetor and Ursus.

All

without exception, the owners of cars dream that their iron horse

served as long as possible, and at the same time broke as little as

possible. To do this is, in fact, quite straightforward.

In the first place you should pay attention to the lubrication system. As you know, the details of the car systems are moving relative to each other. Between them there is friction, which actively prevents this movement.

Details are heated and wear out. As a result, jamming of parts. To reduce friction, different lubricants are used in the car. The gearbox just needs a special oil to reduce gear friction. The oil creates a film on the surface of the gears and removes heat from the parts and prevents corrosion. Therefore,

the owner of the car must remember that the oil is needed not only for

the engine, but for the gearbox and rear axle, if the car with a rear

wheel drive.

The gearbox oil and engine oil are quite different things. For the box, use a special transmission oil. And then, looking at what gearbox in your car is installed.

In the LOCO range, the Platinum Gear LS 80W-90 transmission oil is presented.

This is the all-season transmission oil of the new generation. It is based on the optimum composition of deeply refined mineral base oils with a complex of extra-class additives. Provides

excellent lubrication, maximum protection of mechanical transmissions

and transmissions with limited sliding type LS, intended for operation

in mechanical transmission boxes of cars, trucks and buses working in

difficult operating conditions, where application of oil corresponding

to requirements of class GL-5 is required. according to the API.

Guarantees:

• excellent thermal stability and oxidation resistance;

• good corrosion and rust protection

• Excellent load bearing capacity

• excellent lubricating and anti-wear properties,

• very good anti-foam properties.

If in your car, the automatic gearbox also needs to apply special oil. When the friction clutches start to work, the oil is responsible for their grip, and also effectively cools these clutches.

In our assortment there is also an oil, namely: Platinum Gear ATF III,

intended for use in automatic transmission boxes of cars, trucks and

buses, in which the manufacturer recommends use of oils of type Dexron®

III.

The

Platinum GEAR ATF III oil is also recommended for use in power steering

devices, in hydraulic couplings for cars and trucks, and in hydraulic

systems requiring the use of oils such as ATF.